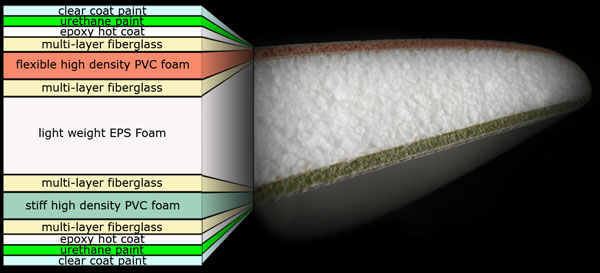

Why a Jimmy Lewis Board? With the proliferation of cheap SUP's on the market.it's time to highlight again what separates a quality board that will last a lifetime, from a nicely painted piece of junk that will start to deteriorate the minute you hand over your hard earned cash. For some, the technical details of board construction is a snooze-fest. But there is a huge difference between construction methods, weight, quality and price. So you need to arm yourself with some simple research and questions. One of your first questions should be about the construction. The materials and method will dictate the weight, flexibility, and durability of your board. And it will help you separate fact from hype from garbage.A key phrase you should hear is "Epoxy PVC Sandwich Construction". Don't fall for catchy names or three-letter descriptions. Jimmy has been using this construction method on his boards for decades. Study the diagram below to learn why it is still the best.  Traditionally, a foam core was simply covered with fiberglass and resin. The advent of the Epoxy PVC sandwich revolutionized the weight and the strength. Instead of thick, heavy layers of glass alone, a shaper could wrap the foam core with thinner layers of glass and flexible sheets of high density PVC foam. The epoxy infused result was a lighter weight skin of PVC foam bridging a layer of glass on either side. Much stronger and lighter than fiberglass alone. Although large scale production includes the use of moulds to bond the layers and set the rocker-line, all of Jimmy's blanks and rails are still shaped and finished by hand. There are no computerized cutting machines popping out board after board. There is, however, a highly skilled group of shapers whose attention to detail meets Jimmy's high standards.

Traditionally, a foam core was simply covered with fiberglass and resin. The advent of the Epoxy PVC sandwich revolutionized the weight and the strength. Instead of thick, heavy layers of glass alone, a shaper could wrap the foam core with thinner layers of glass and flexible sheets of high density PVC foam. The epoxy infused result was a lighter weight skin of PVC foam bridging a layer of glass on either side. Much stronger and lighter than fiberglass alone. Although large scale production includes the use of moulds to bond the layers and set the rocker-line, all of Jimmy's blanks and rails are still shaped and finished by hand. There are no computerized cutting machines popping out board after board. There is, however, a highly skilled group of shapers whose attention to detail meets Jimmy's high standards.

Durability details: You need peace of mind that your hull or fin is not going to rip out the first time you make contact with the ocean floor or the garage floor. Ask if the fin boxes and key points are reinforced with high density PVC foam. This will assure you that the extra mile has been traveled to keep the weight down but the strength up. You'll be surprised to learn how many brands are just using fiberglass.  Automotive Hand-Painted Finish: Jimmy isn't about mass production on the fastest cheapest scale. He'd rather make a functional work of art that riders are proud to own and care for. Every Jimmy Lewis Kite, Paddle, and Surf board is finished with hot coat of epoxy, primer, paint, and clear coats. The Urethane paints and graphics are laid down just like a car would be painted. Each layer is masked and sprayed by hand. The finishing clear coat is hand polished to a deep shine that can only be matched by a high-end luxury car. Recent improvements in the chemical bond make this finish as durable as it is beautiful.

Automotive Hand-Painted Finish: Jimmy isn't about mass production on the fastest cheapest scale. He'd rather make a functional work of art that riders are proud to own and care for. Every Jimmy Lewis Kite, Paddle, and Surf board is finished with hot coat of epoxy, primer, paint, and clear coats. The Urethane paints and graphics are laid down just like a car would be painted. Each layer is masked and sprayed by hand. The finishing clear coat is hand polished to a deep shine that can only be matched by a high-end luxury car. Recent improvements in the chemical bond make this finish as durable as it is beautiful.